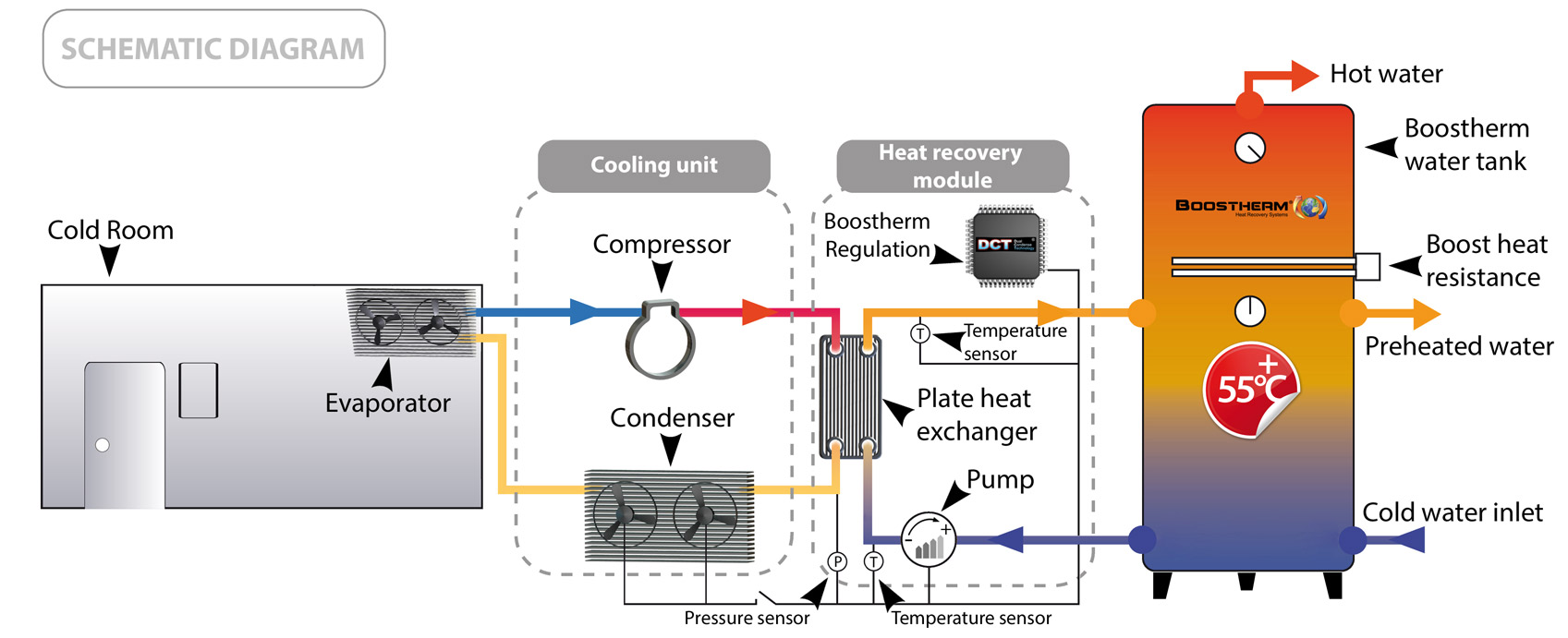

The TRS system is intended for small, medium-sized and larger companies who have on one hand a need for cooling (eg: cold rooms, refrigerated display case) and on the other hand a need for heating water.

By recovering the maximum amount of rejected heat from the refrigeration unit a TRS system can heat significant quantities of water and dramatically reduce energy costs. Suitable for:-

- Hotels

- Bakeries

- Fast Food outlets

- Catering industries

- Large Kitchens

- Hospitals

- Butcher shops

- Restaurants

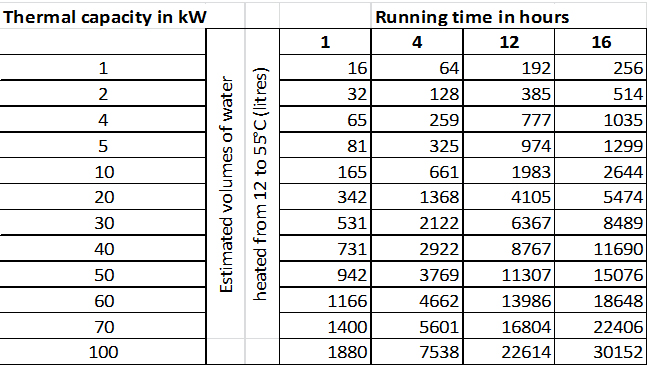

Estimate the volume of water that can be heated…

Heat Recovery Comparison.Hotel- Sample |

|||

| Required maximum water temperature | 63 | ||

| Required quantity of hot water per day | 1000 |

Without Heat Recovery |

|

| Average cold water temperature °C | 18 | Number of Litres heated per 24 hrs | 1000 |

| Off Peak electricity cost ($ /kWhr) | 0.2 | Ground Water temperature °C | 18 |

| Number of days dairy operated per year | 360 | Required temperature °C | 63 |

| Off Peak Electricity costs c/kWhr | 0.2 | ||

| kWhrs required daily to heat your water | 52.34 | ||

| Cost per day | $ 10.47 | ||

| Tons of CO² per year with current use | 24.49 | Cost per year before Heat Recovery | $ 3,768.30 |

| Tons of CO² per year after heat recovery | 4.35 | ||

| Savings of CO² (tons per year) | 20.14 | ||

| Percentage of CO² reduction per year | 82.22% |

With Heat Recovery |

|

| Number of Litres heated per 24 hrs | 1000 | ||

| Water temp in Heat Recovery buffer tank | 55 | ||

| Required temperature °C | 63 | ||

| Off Peak Electricity costs c/kWhr | 0.2 | ||

| kWhrs required daily to heat your water | 9.30 | ||

| Cost per day | $ 1.86 | ||

| Cost per year after Heat Recovery | $ 669.92 | ||

Savings over one year @ current power costs |

$ 3,098.38 |

||

Savings in percentage over one year |

82.22% |

||